Success Added !

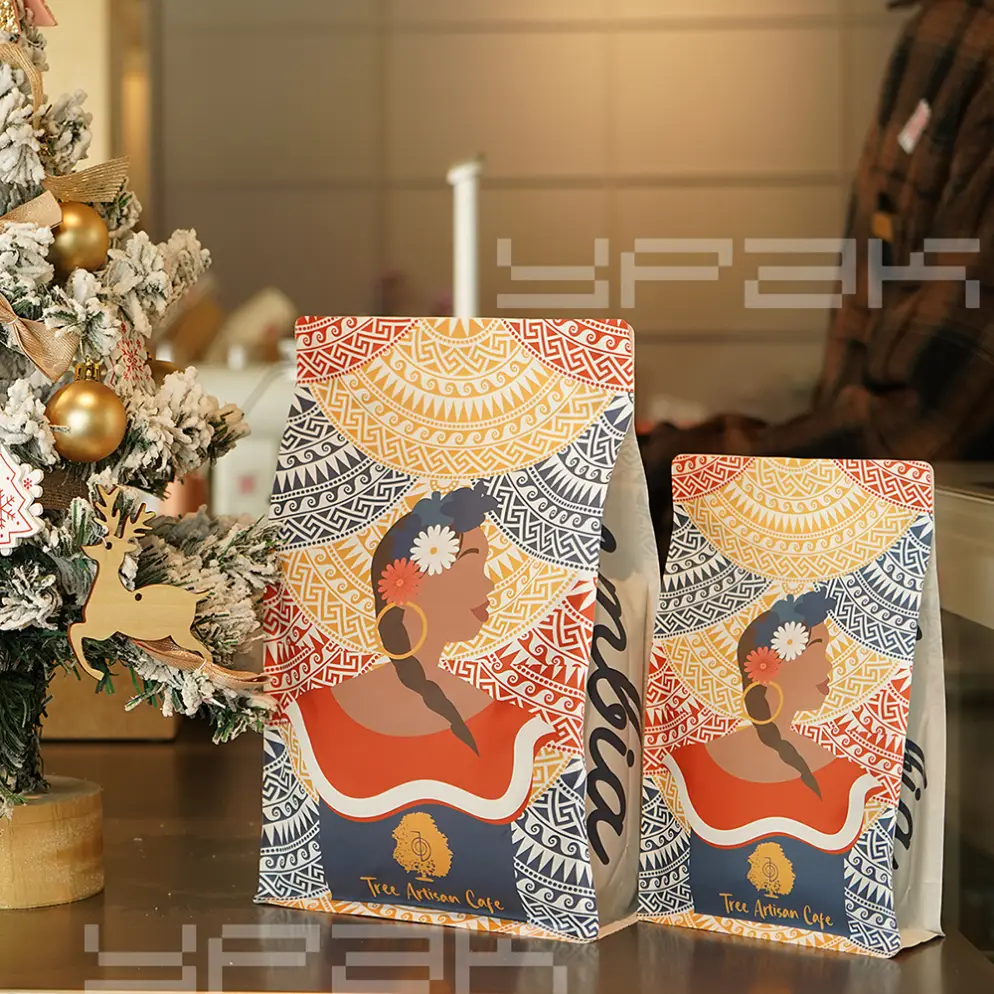

Flat Pouch for Drip Coffee Filter Packaging

A durable flat pouch designed for single-serve drip coffee filters, offering clean protection, clear brewing instructions, and strong suitability for OEM and private-label production.

Build your bag and get a quote

Build your bag and get a quote

DESCRIPTION

SPECIFICATION

HELP CENTER

This Flat Pouch for Drip Coffee Filter is engineered for roasters and manufacturers who need reliable, compact, and brandable packaging for single-serve drip filter discs. Made from high-barrier laminate materials, the pouch protects coffee aroma and maintains freshness when nitrogen-flushed or heat-sealed.

The clear front window highlights the UFO filter design, while the back panel provides step-by-step brewing instructions, making it ideal for retail sampling programs, hotel amenities, and corporate gift sets. Its slim profile reduces storage and shipping volume, supporting large-scale OEM operations and automated filling lines.

The pouch works with various drip filter disc formats, offering excellent sealing stability, moisture protection, and customizable surface printing for brand storytelling. It is well-suited for professional coffee brands expanding into ready-to-brew product lines.

A high-barrier, food-contact flat sachet designed to protect single-serve hanging‑ear/drip coffee filters (typically 7–12 g). Available as pre‑made 3‑side or 4‑side seal pouches, or as printed film rolls for VFFS/HFFS lines. Optimized for aroma retention, shelf life, easy opening, and premium branding.

Key Features

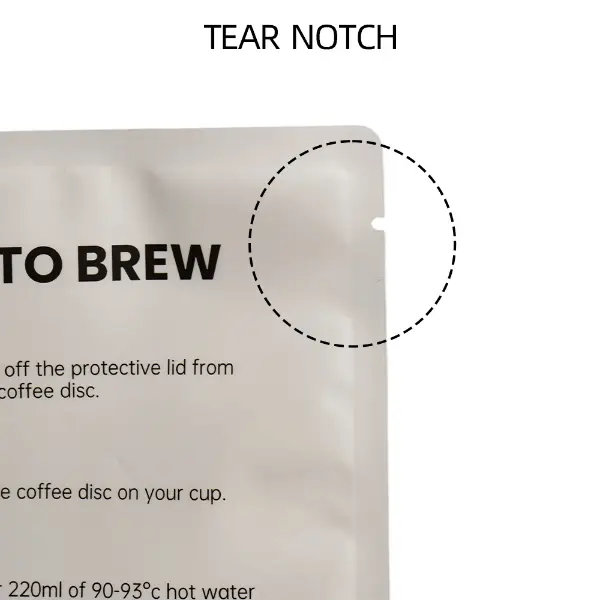

- Formats: 3‑side seal and 4‑side seal flat pouches; optional euro‑slot for peg display; laser scoring and tear notches for easy open.

- Barrier protection: Engineered for coffee—low oxygen and moisture transmission to support nitrogen flush and extended freshness.

- Window options: Clear, matte‑clear, or fully opaque; paper‑touch finishes and kraft look available.

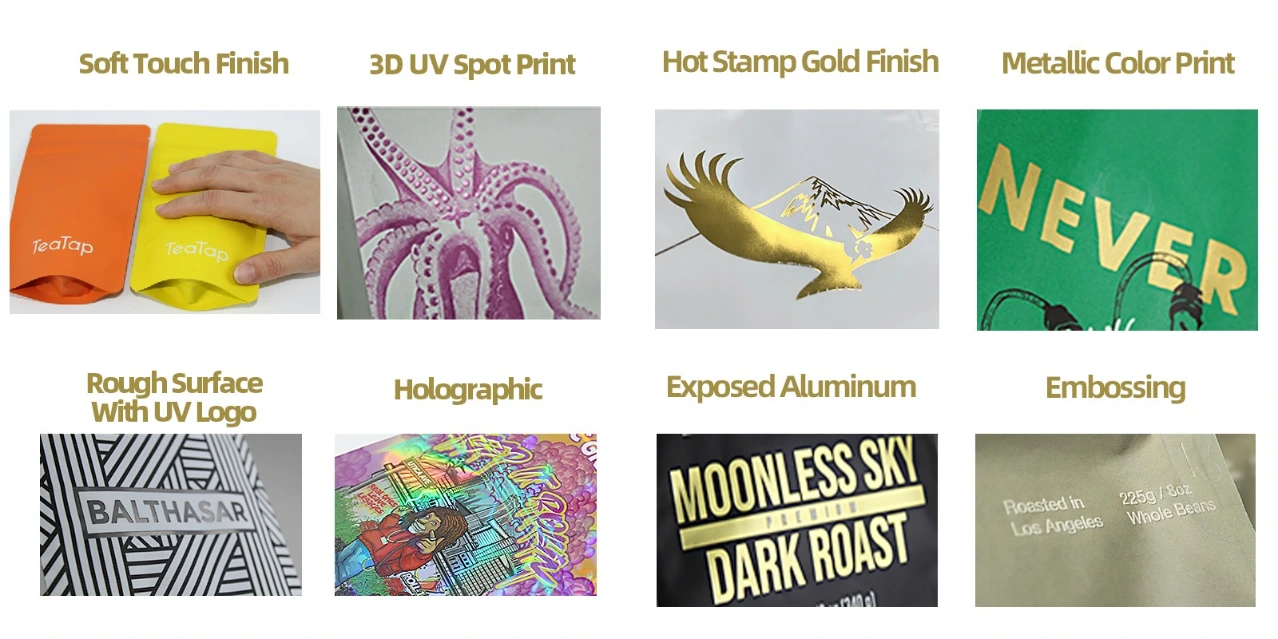

- Print quality: Gravure or offset‑like high fidelity (up to 8–10 colors), CMYK + Pantone, matte/gloss, registered matte, soft‑touch, spot varnish, foil accents.

- Branding and codes: Space for barcodes/QRs, batch/lot dates; registration marks for automated lines.

- Food safety: Food‑contact laminates, compliant with common regulations (FDA/EU); material declarations available on request.

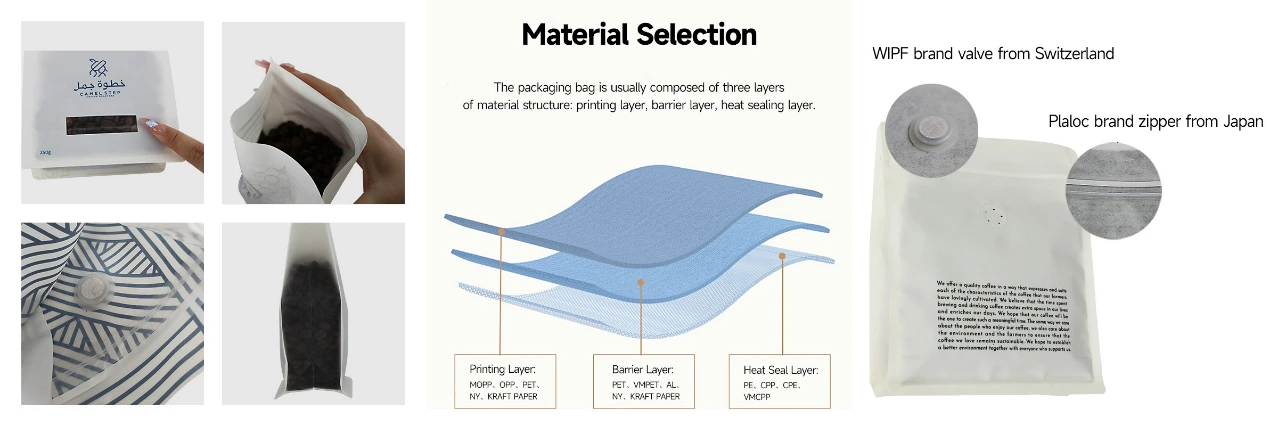

Typical Material Structures

- Premium high barrier:

- PET/Al/PE or PET/VMPET/PE for very low OTR/WVTR and strong aroma lock.

- Matte OPP/PET/PE for soft‑touch with barrier.

- Recyclable mono‑material options:

- PE/EVOH/PE or all‑PE high‑barrier laminates for LDPE stream recycling (design‑for‑recycling).

- PP‑based OPP/CPP (regional recyclability varies).

- Paper‑based and compostable:

- Paper/VMPET/PE for kraft aesthetics with strong barrier.

- Cellulose (NatureFlex)/metalized cellulose + bio‑sealant for plastic‑lite solutions (verify barrier and local compostability).

Note: We will recommend a structure based on your target shelf life, fill method (nitrogen flush/oxygen absorber), and local recycling goals.

Barrier Performance (typical ranges, confirm per spec)

- Oxygen transmission (OTR): down to <1 cc/m²/day for aluminum or top metalized structures; <5 cc/m²/day for advanced mono‑material films.

- Moisture transmission (WVTR): commonly <1–3 g/m²/day with high‑barrier laminates.

Sizes and Capacity

- Fits standard hanging‑ear filters with ground coffee 7–12 g.

- Common flat pouch footprints (customizable): width 90–110 mm; height 120–160 mm; finished seal widths 6–10 mm.

- Provide your inner filter bag dimensions (W × H × thickness) for a precise dieline and snug fit.

Supply Forms

- Pre‑made pouches: Delivered flat, pre‑sealed on two or three sides; ready for manual or semi‑auto packing and final top seal.

- Printed film rolls: For VFFS/HFFS. Standard 3‑inch cores; roll width and print repeat per machine spec; registration marks and eye marks included.

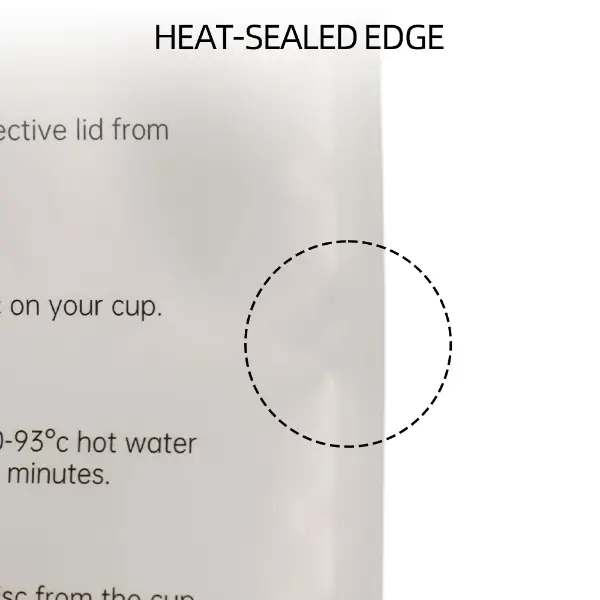

Machine Compatibility and Sealing

- VFFS/HFFS compatible; support for nitrogen flushing.

- Typical seal jaw temps:

- PE sealant: ~130–160°C

- CPP sealant: ~120–140°C

- Paper‑laminate with dispersion coatings: tune per spec and dwell time

- Options: Anti‑static treatments, slip/friction tuning for high‑speed runs.

Optional Features

- Laser tear, easy‑tear notches, rounded corners.

- Deoxidizer/oxygen absorber pouch space call‑out.

- Micro one‑way valve available on request (less common for flat drip sachets).

- Anti‑scratch/matte coatings for premium feel.

Sustainability Choices

- FSC paper outers, recycled content films where applicable.

- Design‑for‑recycling mono‑PE or mono‑PP where regional streams exist.

- Bio‑based/compostable films for low‑volume specialty runs (confirm barrier and certification).

Compliance and Food Contact

- All film layers and inks/adhesives specified for indirect food contact; migration reports available.

- Meets typical regulatory requirements for major markets; provide target countries to confirm.

MOQ, Sampling, and Lead Times

- Pre‑made printed pouches: typical MOQ 10,000–30,000 pcs depending on colors/finishes.

- Printed film rolls: typical MOQ 200–300 kg (varies by structure and print stations).

- White samples/dieline checks: ~2–5 days.

- Printed prototypes: ~5–10 days after artwork.

- Production: ~10–20 days from approval; allow extra for specialty finishes.

Quick Quote Checklist

- Inner filter bag size and fill weight (e.g., 10 g; W × H × thickness).

- Pouch format (3‑side or 4‑side seal) and exact finished size.

- Film structure preference (e.g., PET/VMPET/PE, mono‑PE high barrier, kraft look).

- Window needed or full‑opaque; matte/gloss/soft‑touch requirements.

- Printing details (colors, special finishes), barcodes/QRs, variable data area.

- Packing method (manual/semi‑auto/VFFS/HFFS), nitrogen flush, oxygen absorber.

- Target shelf life, sustainability goals, quantity, and delivery timeline.

Product Feature

- High-barrier flat pouch for drip filter packaging

- Supports nitrogen flushing and secure heat sealing

- Clear printing space for logos and instructions

- Slim, lightweight, cost-efficient for bulk shipping

- Compatible with UFO-style and other drip discs

- Matte surface option for premium presentation

- OEM / ODM customization available

- Suitable for automated filling and sealing lines

Application Areas

- Japan, South Korea, Taiwan

- China, Hong Kong, Singapore

- USA, Canada

- Germany, UK, France

- Saudi Arabia, UAE, Qatar

Target Audience

- Specialty coffee roasters

- Drip filter manufacturers

- OEM / ODM coffee product suppliers

- Retail coffee brands

- Hotel and hospitality buyers

- Importers and distributors

- Corporate gifting companies

Product Parameters

| Brand Name | YPAK |

| Material | Post-Consumer Recycled Material |

| Place of Origin | Guangdong, China |

| Industrial Use | Food, tea, coffee |

| Product Name | Coffee Pouch |

| Sealing & Handle | Zipper Top |

| MOQ | 500 |

| Printing | Digital printing/Gravure printing |

| Keyword | Eco-friendly coffee bag |

| Feature | Moisture Proof |

| Custom | Accept Customized Logo |

| Sample Time | 2-3 Days |

| Delivery Time | 7-15 Days |

Product Display

We use environmentally friendly materials to make packaging to ensure that the entire packaging is recyclable/compostable. On the basis of environmental protection, we also provide special crafts, such as 3D UV printing, embossing, hot stamping,holographic films, matte and gloss finishes, and transparent aluminum technology, which can make the packaging special.

Frequently Asked Questions

-

Are you a manufacturer of packaging bag?

Yes. We are a manufacturer of the flexible packaging bags with 15 years of experience in Guangdong Province.

-

Will using recyclable packaging increase the cost of coffee bags?

Yes, the cost of using this advanced, certified recyclable material is indeed higher than that of traditional non-recyclable aluminum-plastic composite packaging at present. However, this investment reflects your brand's genuine commitment to sustainable development, which can effectively enhance the brand image, attract and retain environmentally conscious consumers. The long-term value it brings far exceeds the initial cost increase.

-

How does the preservation effect of this recyclable bag compare with that of traditional packaging with aluminum foil?

Please rest assured completely. The oxygen barrier performance of EVOH is even better than that of aluminum foil. It can more effectively prevent oxygen from invading and the loss of coffee aroma, ensuring that your coffee beans maintain a fresh flavor for a longer time. Choose it and you don't have to make a trade-off between preservation and environmental protection.

-

Are the seals (zipper) and valves of the bags also recyclable? Whether it needs to be handled separately?

We are committed to maximizing recyclability. The entire bag is 100% recyclable, including the seal (zipper) and the valve. No separate handling is required.

-

How long is the service life of this kind of packaging bag?

Under normal storage conditions, the service life of our recyclable coffee bags is usually 12 to 18 months. To ensure the freshness of the coffee to the greatest extent, it is recommended to use it as soon as possible after purchase.

-

Still have questions?

Can't find the answer you're looking for? Please chat to our friendly team.

Sign up to our Newsletter

Give your inbox some love with new products, tips, & more.